CONCRETE Form[ing]work:

Design, Fabrication, Simulation and Correlation of Parametrically Patterned Flexible Formwork and Concrete

Supervisors: Oliver Tessmann, Jonas Runberger

Full manuscript available via KTH Diva Portal

CONTEXT

Concrete is one of the most commonly used construction materials, yet industrial fabrication continues to default to established standards of planar formwork and uniform cross-sections for the sake of simplicity and predictability. The research conducted within Concrete Form[ing]work explored alternative methods of producing concrete formwork with a simple, technical re-imagination of material: exchanging the familiar, i.e., rigid wood, for flexible fabric.

SMOCKING

This research includes a comprehensive investigation of the potential of smocking as a means of tailoring complex formwork. Smocking is a centuries-old patterning technique of gathering and pinching fabric; its distinct feature is the ability to transform a flat sheet of gridded material into a complex surface without the extensive tailoring of custom pieces.

Chapter Organization

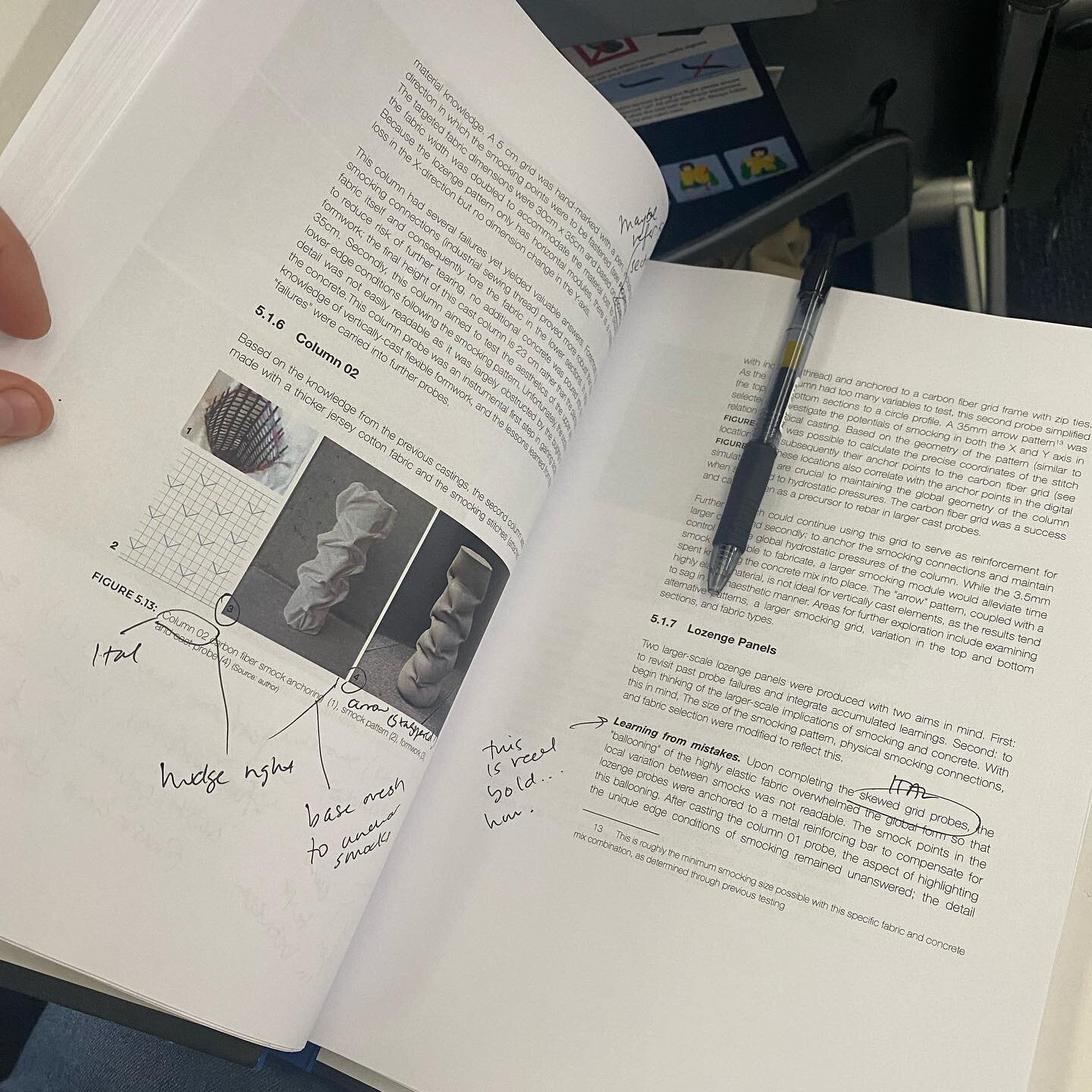

MATERIAL:

casting in smocking

Research Questions:

How can fabric formwork be re-envisioned using smocking to create novel concrete-casting techniques?

GEOMETRICAL:

Computational Pattern Generation

How can smocking be parameterized and differentiated to articulate new methods of fabricating architectural elements?

DIGITAL:

Simulation and Correlation

What are the possibilities and limitations of simulating flexible formworks and correlating them with cast counterparts?

MATERIAL

In the realm of flexible formwork and cast concrete, computationally generated non-standard forms typically result in impractical tailoring of multi-component formwork. The utilization of smocking introduces an alternative method for the shape manipulation of flexible membranes without the need to cut numerous individual components. By decreasing the complexity of fabrication without compromising form, the potential of smocked formwork was deemed worthy of investigation. The relationship between cast concrete and smocked fabric was of particular interest, raising questions regarding how individual patterns would respond to hydrostatic pressures.

ORINUNO tool workflow - available via Github

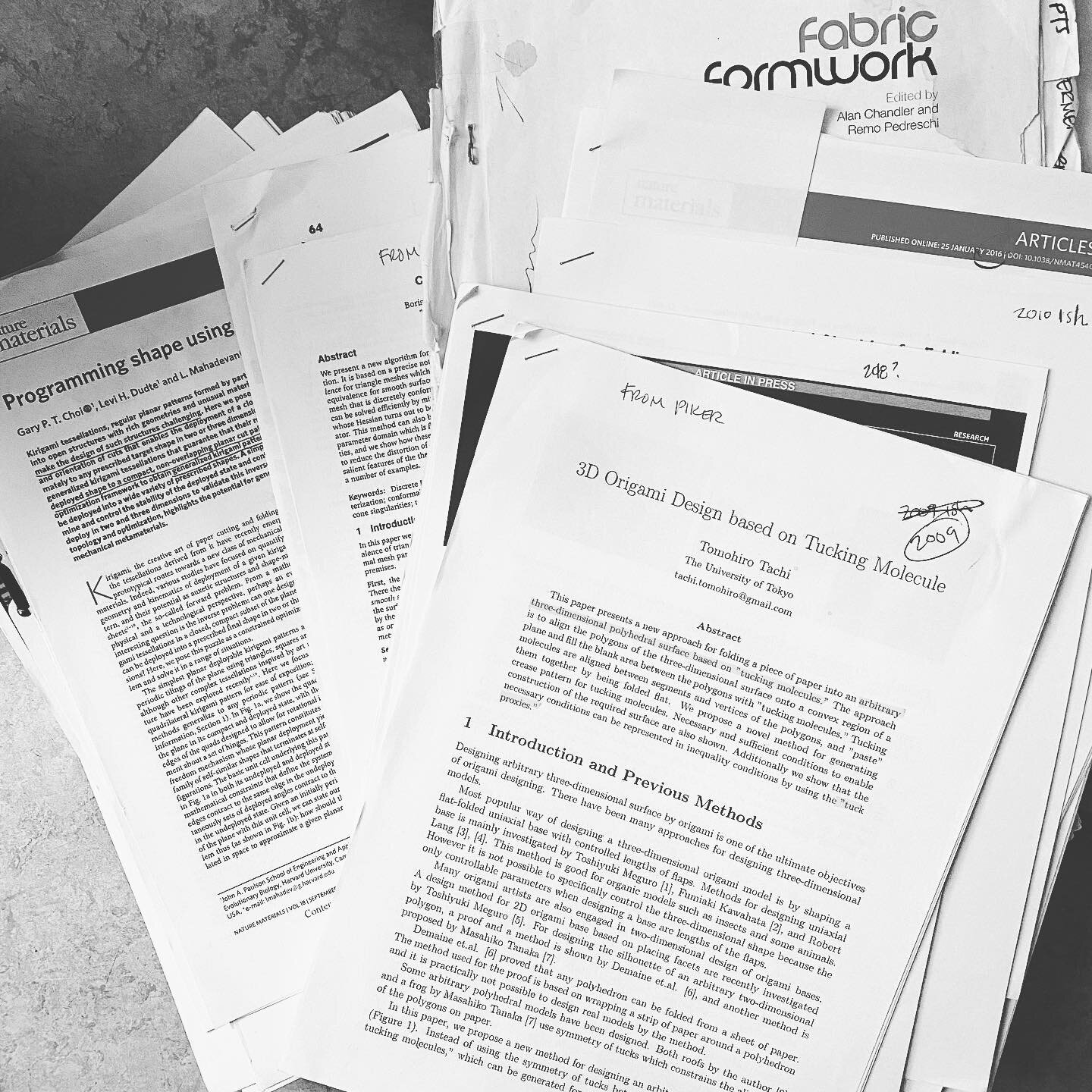

GEOMETRICAL

By cataloging the related research fields of mesh unrolling, origami, kirigami origami, auxetic materials and conformal mapping in great depth, the research presented in this thesis has developed a digital tool, OriNuno, that deconstructs double-curved geometries into smocking patterns. OriNuno exemplifies the ability to program both local and global geometrical articulation with parametric smocking, allowing for the sustainable fabrication of complex forms from a single sheet of material.

WALL THREE

Wall Three is a permanent installation at Frihamnstorget in Stockholm, Sweden. Constructed of Concrete Canvas, this wall demonstrates the ability to sustainably fabricate doubly-curved architectural elements from flat sheet material.

The Wall Three demonstrator put into practice all of the learnings gained from previous experiments and investigated the implications of the large-scale fabrication of smocked concrete textiles. In this case, the designer (author) literally became the fabricator, as the visualization and simulation tools were tested first-hand during the construction of this demonstrator. From pattern generation and design to simulation, correlation, panel fabrication and wall assembly, the construction process of this demonstrator integrated the knowledge and experience gained through the experiments conducted during the research presented in this thesis.

DIGITAL

The simulation ‘group’ of OriNuno contributes to bridging the disconnect between material and form, as well as designer and fabricator. This thesis addresses the current inability to reliably simulate flexible formwork in today’s industry, which resulted in an impetus to create an accessible digital tool that facilitates digital simulation of and correlation to physical casts. OriNuno not only parametrically deconstructs input shapes into patterns but also simulates both the fabric smocking and casting processes, facilitating accurate correlation between simulations and casts. Developed in parallel with feedback from numerous physical experiments, OriNuno forms a circuitous feedback loop between design, fabrication and correlation between simulation and casting. Bridging the disconnect between these fields allows materiality to inform and, ultimately be exhibited in design.

Video Documentation

See in progress details on instagram @concreteformingwork

![Annie Locke Scherer CONCRETE Form[ing]work Wall Three Photo By Fredric Boukari](https://images.squarespace-cdn.com/content/v1/525212bfe4b05f3f0155884c/b09dd5a9-3b73-44dc-96fd-dd3e8a0a38dc/ALScherer_CONCRETE+Form%5Bing%5Dwork_WallThree_Photo+By+Fredric+Boukari)

![Annie Locke Scherer CONCRETE Form[ing]work material: casting in smocking](https://images.squarespace-cdn.com/content/v1/525212bfe4b05f3f0155884c/10632f69-def3-4e5d-a13c-b83de5c96688/Annie+Locke+Scherer+CONCRETE+Form%5Bing%5Dwork+material%3A+casting+in+smocking)

![Annie Locke Scherer CONCRETE Form[ing]work Geometrical: Computational Pattern Generation](https://images.squarespace-cdn.com/content/v1/525212bfe4b05f3f0155884c/8ce550fb-adc1-4fd8-aeca-3c7584188eb2/Annie+Locke+Scherer+CONCRETE+Form%5Bing%5Dwork+Geometrical%3A+Computational+Pattern+Generation)

![Annie Locke Scherer CONCRETE Form[ing]work Digital: Simulation and Correlation](https://images.squarespace-cdn.com/content/v1/525212bfe4b05f3f0155884c/84974d02-9291-41b7-85f5-431a3b5262a0/Annie+Locke+Scherer+CONCRETE+Form%5Bing%5Dwork+Digital%3A+Simulation+and+Correlation)

![Annie Locke Scherer CONCRETE Form[ing]work smocking pattern, fabric formwork and cast](https://images.squarespace-cdn.com/content/v1/525212bfe4b05f3f0155884c/a8b88929-2bc3-4ea2-b585-b43edae2f6f1/Annie+Locke+Scherer+CONCRETE+Form%5Bing%5Dwork+smocking+pattern%2C+fabric+formwork+and+cast)

![Annie Locke Scherer CONCRETE Form[ing]work smocked formwork and cast column](https://images.squarespace-cdn.com/content/v1/525212bfe4b05f3f0155884c/97a43de1-3984-40dd-9c06-27a44a439945/Annie+Locke+Scherer+CONCRETE+Form%5Bing%5Dwork+smocked+formwork+and+cast+column)

![Annie Locke Scherer CONCRETE Form[ing]work OriNuno smocking pattern generation tool](https://images.squarespace-cdn.com/content/v1/525212bfe4b05f3f0155884c/39451d3c-2bf7-40b6-a384-3bf00cfd943a/Annie+Locke+Scherer+CONCRETE+Form%5Bing%5Dwork+OriNuno+smocking+pattern+generation+tool)

![Annie Locke Scherer CONCRETE Form[ing]work smocking pattern generation](https://images.squarespace-cdn.com/content/v1/525212bfe4b05f3f0155884c/cd98ed0f-a53e-4f6b-bff5-f10837a85c1a/Annie+Locke+Scherer+CONCRETE+Form%5Bing%5Dwork+smocking+pattern+generation)

![Annie Locke Scherer CONCRETE Form[ing]work Wall Three](https://images.squarespace-cdn.com/content/v1/525212bfe4b05f3f0155884c/a96d68e3-1886-4cae-9eb6-5fc8bac381b4/Annie+Locke+Scherer+CONCRETE+Form%5Bing%5Dwork+Wall+Three)

![Annie Locke Scherer CONCRETE Form[ing]work Smocking variation](https://images.squarespace-cdn.com/content/v1/525212bfe4b05f3f0155884c/d7bbc038-2cf1-4737-9e94-224bb4896341/Annie+Locke+Scherer+CONCRETE+Form%5Bing%5Dwork+Smocking+variation)

![Annie Locke Scherer CONCRETE Form[ing]work Concrete smocking cast and scan correlation](https://images.squarespace-cdn.com/content/v1/525212bfe4b05f3f0155884c/9682338a-cae8-4737-bb46-2de44cf5150b/Annie+Locke+Scherer+CONCRETE+Form%5Bing%5Dwork+Concrete+smocking+cast+and+scan+correlation)

![I would like invite you all for my doctoral defense of my dissertation: “CONCRETE FORM[ing]WORK: Design, Fabrication, Simulation and Correlation of Parametrically Patterned Flexible Formwork and Concrete.”

This research is part of a proj](https://images.squarespace-cdn.com/content/v1/525212bfe4b05f3f0155884c/1637148917389-BP5DYYLKEAXNP5VLVMBQ/image-asset.jpeg)

![It is with great pleasure that I present to you my printed dissertation: “CONCRETE FORM[ing]WORK: Design, Fabrication, Simulation and Correlation of Parametrically Patterned Flexible Formwork and Concrete”

It’s been a wild five yea](https://images.squarespace-cdn.com/content/v1/525212bfe4b05f3f0155884c/1637148917836-ATWFVOAN5U9CS5C8ON2J/image-asset.jpeg)